top of page

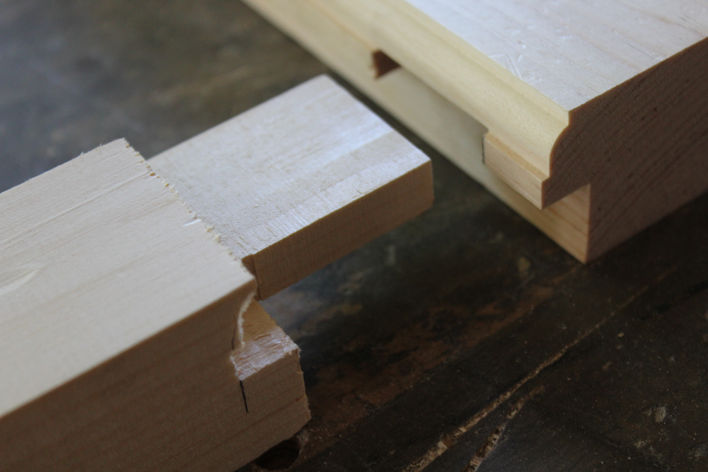

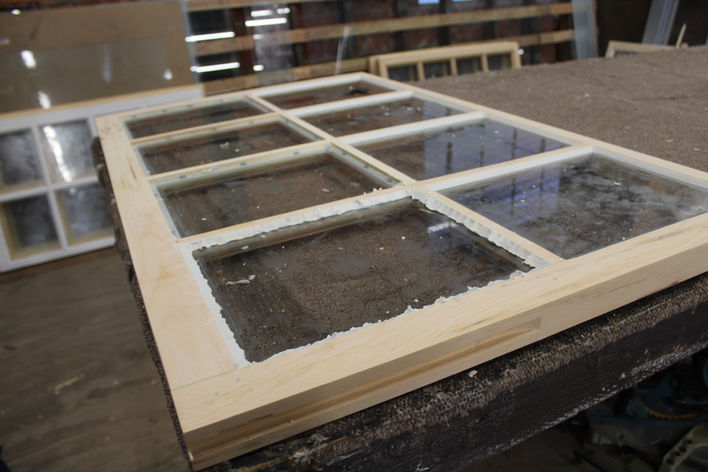

Using Time-Tested Techniques, We Take Pride in Every Sash We Build.

Using Time-Tested Techniques, We Take Pride in Every Sash We Build.

“Our customers are often people that share our passion for time tested products that can invest upfront for the longevity of their homes” ~ Chesley Devlin

bottom of page